Aluminum foil packaging bag manufacture process

The aluminum foil packaging bag may not be well understood by everyone. Simply put, a layer of aluminum foil is plated on it, so the aluminum foil bag generally has a silver appearance, or the inside of the bag is silver, and the aluminum foil is isolated and quite superior to other materials. So it will take longer to save the item.

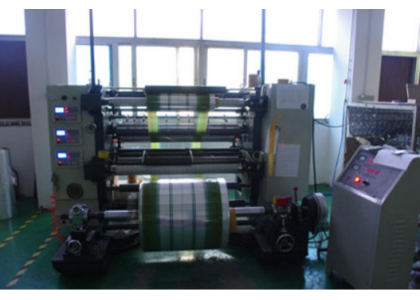

The process of packaging aluminum foil is: aluminum foil unwinding → gravure printing → drying → coating protective layer → drying → coating adhesive layer → drying → aluminum foil winding.

In the whole production process, the surface quality of the gravure printed character pattern and the heat seal strength to be achieved by the adhesive layer, the adhesion of the protective layer and the drying temperature and the speed and tension control of the coating machine operation are need to be strictly controlled.

Therefore, in the "Aluminum Foil for Pharmaceutical Packaging" national standard, there is a clear requirement for the surface quality of medicinal aluminum foil printed characters, and physical and chemical properties for the properties of the protective layer and the adhesive layer, thereby protecting the medicinal PTP aluminum foil from having good barrier properties. , hygienic safety, heat sealability and good physical and mechanical properties.

In order to achieve the above requirements in the PTP aluminum foil printing and coating production process, it is necessary to be familiar with the properties of the applied raw materials, and pay attention to the following problems during the operation:

1.Master the characteristics of aluminum foil and printing ink

2.The amount of solvent added to the ink should be appropriate

3.Adhesive should meet the requirements